Medical Isolated Power System Design and Installation Instruction

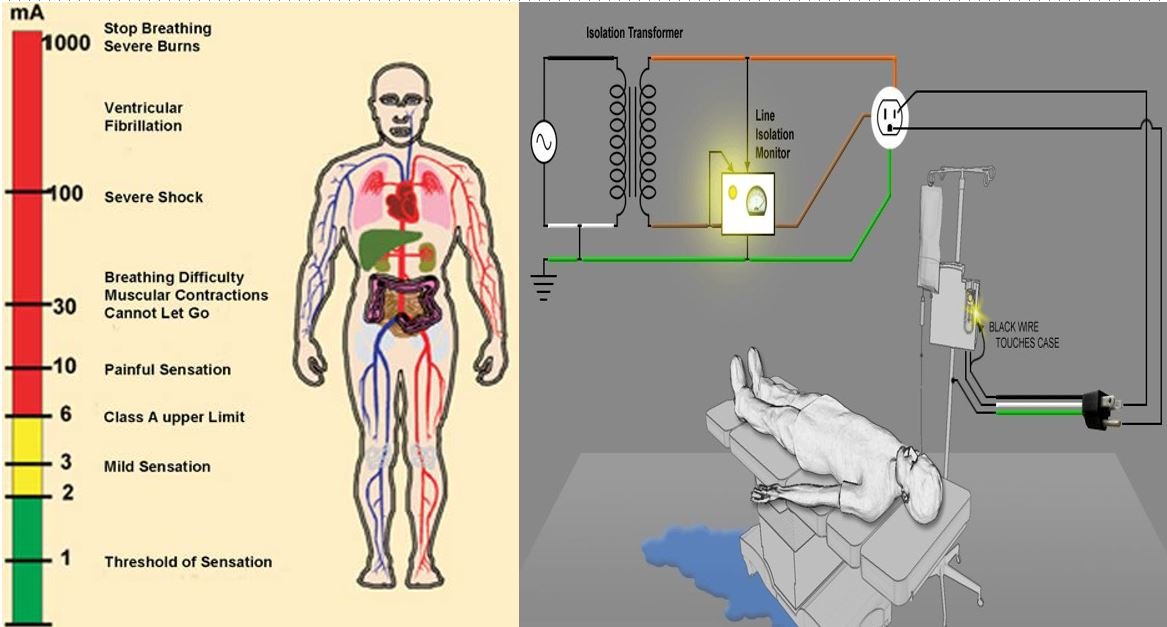

Isolated Power System is ungrounded power source (IT), use medical grade low leakage isolation transformer to isolate the Neutral from the Earth, but due to the leakage current produced by the insulation of the wires and the loads so we need to minimize this hazard current under the specified limit to avoid any leakage current to pass through the patent when the used medical equipment got failure. The following instructions should be followed to achieve maximum isolation in the isolated power system:

1.

Recommended to use maximum

10 KVA isolation transformer per panel to minimize the leakage/hazard current

produce by the medical Load.

2.

For special high-power

loads like X-ray & Laser, should not be supplied with the same IPP for

medical loads, a dedicated IPP for this load should be used with higher KVA

rating if required.

3.

16 Circuits maximum can be

used for each isolation transformer.

4.

Due to the transformer initial current which

may exceed 8 x transformer nominal current, it is recommended to use upstream

protection with adjustable trip delay time, or size the protection 10-20 Amper

higher than the one used in the isolation panel.

5.

To minimize the leakage

current produced by Isolated Power Panel (IPP) outgoing wiring the panel should

installed as close as possible to the load, so better to installed inside the

room (OR, ICU, …).

6.

Remote indicator is

required to duplicate the alarm of the Line Isolation Monitor (LIM) to the

medical staff inside the room that incase of the panel installed outside the

room.

7.

The medical equipment only

(which will serve the patent) should be supplied from the Isolated Power Panel

(IPP), like pendant sockets dedicated for medical equipment, surgical light.

Other loads will not contact with the patent like lighting, wall monitors, wall

panels, etc. Must Not supplied from IPP, this type of load will increase

the leakage/hazard current of the isolated system.

8.

The outgoing wiring of the

IPP should be low leakage type like XHHW for both power conductors, for

grounding conductor normal cable can be used.

9.

The total length of the

IPP’s out going circuits (sum of length of all circuits) should not exceed 150

meters to minimize the leakage/hazard current produce by the wire.

10.

Do not use pulling

compounds to lubricate inside of conduit.

11.

Use conduit with larger

diameter to avoid damage to wire insulation during pulling the wire.

12.

The outgoing wiring of the

IPP must not be pulled in the same cable try or conduit of non-isolated wiring

(like incoming cable) or isolated wiring of another IPP.

13.

The growing terminal of all

loads supplied by the IPP (including the grounding of the floor) must be

connected the ground bar inside the IPP.

14. If there is more than one IPP used inside the same room, the grounding bars of all of them must be bonded together